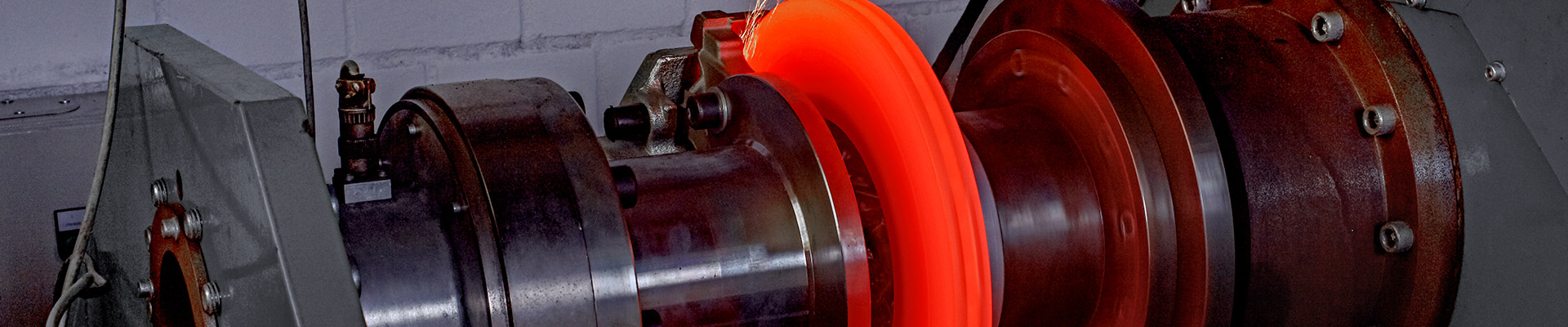

Testing brakes in the component test bench

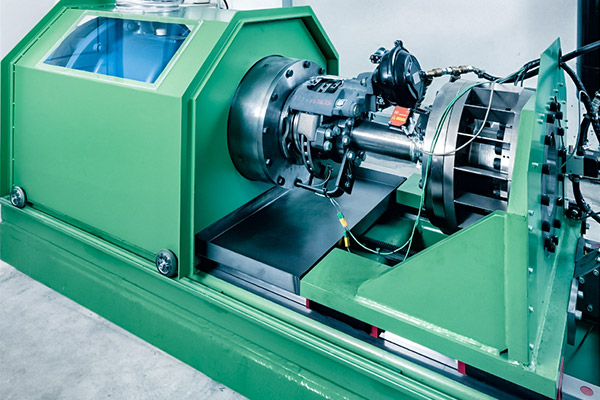

Individual components of the transmission can be tested efficiently by ATESTEO in our component test benches. Through customized scaling and adaption of the component test benches to your specific testing needs, ATESTEO can react rapidly and flexibly to new challenges. When it comes to testing braking performance, in our component test benches, we carry out all relevant test programmes in accordance with international, national, and factory standards. In addition, we also solve special tasks for special applications and set up individual test benches.

Component testing in the brake laboratory

Component testing at ATESTEO includes tear, performance, and wear tests, along with NVH (noise, vibration, harshness) tests. In addition, we conduct necessary homologation. Besides fulfilling the standards for commercial vehicles, passenger vehicles, and motorcycles, we have the component test benches to execute special services pertaining to motor sport, industry, or shipbuilding. For your customized needs, ATESTEO has tailor-made arrangements and various component test benches.

Contact

Do you have individual requirements for your brake testing? Our experts will be happy to answer your questions.

We are looking forward to your message!

Our component test benches for brake testing

- Utility (commercial) vehicle flywheel mass brake test bench

- Passenger car flywheel mass brake test bench

- Motorcycle flywheel mass brake test bench

- Running-in test bench

- Drag torque test bench

- Semidynamic strength test bench for disc and drum brakes

- Characteristic curve test bench for pneaumatic brake cylinders

- Mechanisms for hysteresis measurement and adjustment effectiveness measurement

Brake testing for your individual test procedures

- Brake tests in accordance with international procedures and standards such as, for example, ISO, SAE, JASO, and FMVSS

- Homologation in accordance with EWG and ECE

- Testing according to factory standards

- Test service for motor sport

- Strength testing

- Determination of the characteristic curves of brake cylinders

- Hysteresis measurement

- Testing the effectiveness of adjustments

- Determination of residual torque and drag torque

- Dynamic testing programmes

- Track simulation; for example, Rossfeld, Nürburgring