Highly available, flexible torquemeters

Torquemeters from ATESTEO measure the loads and torque arising in the drivetrain and supply measurement data for test bench control and analysis purposes. The high precision of standardised torquemeters and the flexibility in the design of highly specialised multi-channel torquemeters are an absolutely essential requirement for high test bench capacity utilisation.

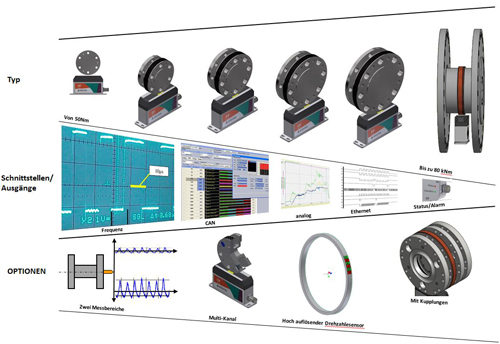

Overview of our torquemeters

- 100 … 10,000 Nm

- 25,000 rpm

- Space-saving due to extremely short construction

- Fully digital, 3 DMS amplifiers

- Standardised DIN flange sizes

- No stator ring

- 20 … 500,000 Nm

- 30,000 rpm

- Optical data transmission (EMV insensitive)

- Optional second torque range

- Integrated evaluation unit

- Optional optical/magnetic speed detection

- 50 … 200 Nm

- 40,000 rpm

- High speed torque transducer

- Optical data transmission (EMV insensitive)

- 1 … 50 Nm

- 15,000 rpm

- Ideal for drag torque measurements

- Optical data transmission (EMV insensitive)

- Optional second torque range

- 200 … 1,000 Nm

- 20,000 rpm

- Low mass inertia

- Increased speed stability

- Central bore for the mounting of a 2nd shaft

- 5 … 20 Nm

- 20,000 rpm

- Ideal for production lines / laboratory applications

- High accuracy due to one-sided bearing

- Compact and handy design / cost-effective

https://youtu.be/dODNQr3mNTM

Certified calibration facility in the ATESTEO calibration laboratory

New technologies in data transmission and further development of the design guarantee that even future requirements are accounted for, above all with regard to ease of handling in combination with providing highly precise measurement data. The product quality of ATESTEO’s own torquemeters is ensured by certified calibration equipment. Our DAkkS-certified calibration laboratory also offers this service for third-party products.

Customised measurement shafts and torque measuring flanges

The standardly available measurement shafts for the various measurement ranges are torquemeters that are all similarly built. For easy installation, there are fastening flanges on both ends of the element, which is produced from one piece. The sensor telemetry used is variable and can therefore offer special options in line with the multi-channel ability. In addition, there is a rotational speed sensor with every measuring element.

ATESTEO offers application-specific custom-tailored solutions in addition to standard torque measurement shafts. The sensor telemetry used is variable and can offer special options. Examples of customer solutions may include:

- Capacity for multiple channels; for example, torque and temperature

- Stationary shafts — passive and active

- Sensing shafts made of titanium

- Various geometric variations for stators and rotors

- Roters with holes for the shaft

- Customer-specific measurement ranges

Individual request

Do you have specific requirements for your torque measuring shaft? Just send us an e-mail with your individual request. We will be pleased to advise you!

We are looking forward to your message!

The ATESTEO torque flanges in detail

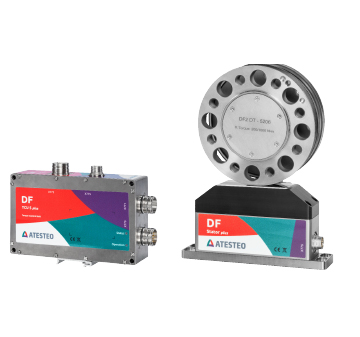

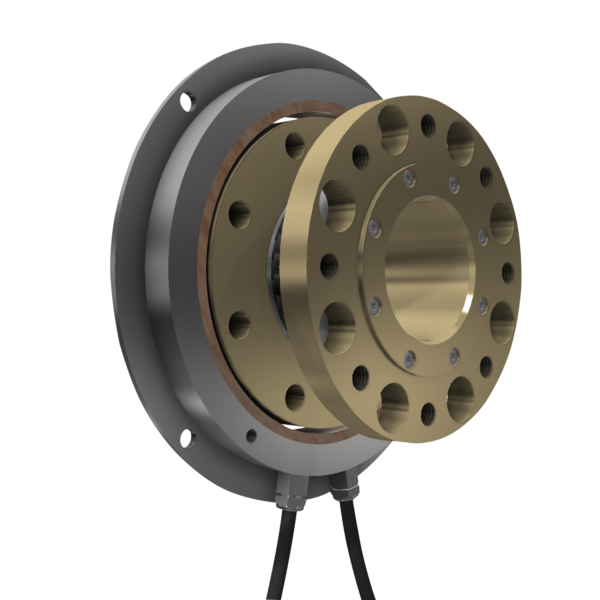

DF series torque measuring flanges

The DF series torque measuring flanges feature an innovative measuring element in combination with digital multi-channel telemetry. This enables an extremely wide bandwidth of installation and measurement arrangements. The torquemeter is unique in that it features three genuine strain gauge amplifiers electronics of the rotor. The additional overflow channel transmits measurement values of up to 300% of the nominal torque. The rotor temperature is also signaled. The flange dimensions of the DF series conform to the DIN norm and are compatible with existing systems.

Features torquemeters DF series

- DIN flange dimensions combined with a compact design

- The one-sided and hollow measuring element can, as an option, be positioned on to the drive shaft for assembly purposes (inline concept). Critical operating parameters such as “linkable masses” or limited limiting speeds can thus be deactivated.

- Owing to the elimination of the stator ring and the broad positioning distance between the rotor and the stator head, the overall installation of the measuring system and the replacement of the individual components is very easy. The evaluation unit necessary for the operation of the measuring system makes all interfaces available for easy and timely processing of the measuring data.

- The mostly free design of the torque measuring element offers an additional expansion as a two-range measuring flange up to a torque ratio of up to 1:5 without expecting appreciable restrictions of the mechanical properties.

- Comprehensive diagnostic possibilities: Over Ethernet and CAN, the rotor temperature and overload torsional value, for instance, can be output up to 300% over the nominal (rated) value.

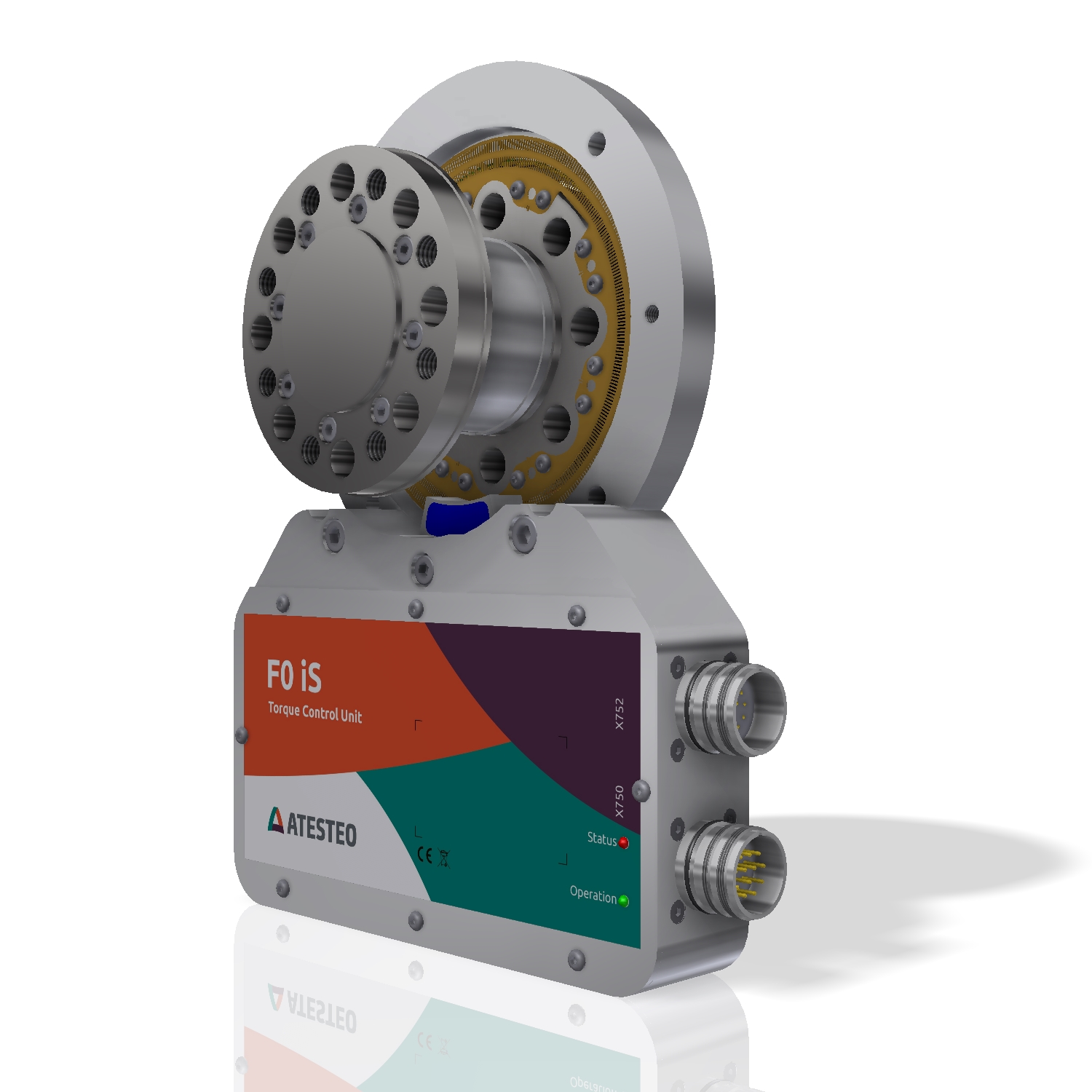

F-series torque measuring flanges

The torque measuring flanges of the F series are torquemeters that use infrared high-power LEDs to transmit data. They are completely immune to EMC (electromagnetic compatibility) during optical signal transmission and also do not radiate electromagnetic waves. Designed as two-range sensing shafts, these torque measuring flanges greatly shorten your setup times. The various sizes of these torque measuring flanges each cover a very large range of torques.

Features torquemeters F series

- Measurement range from 20 Nm to 150,000 Nm

- Standard measuring precision 0.05% in the measuring ranges up to 20 kNm

- Multidimensional temperature detection for optimal compensation

- Integrated rotational speed measurement as standard

- High-speed performance up to 30,000 rpm possible

- Optional two torque ranges

- Optional high-resolution magnetic rotation measurement system

- Variation with separate stator electronics is deliverable

HSTT series torque measuring flanges

The torque measuring flanges of the HSTT series are torque measuring shafts for high speeds. The torque measuring flanges are speed-resistant up to 45,000 rpm and therefore first choice for new tasks in e-mobility testing. They have a titanium rotor. Their low weight of 400 grams makes them ideal for electrical machines where the mass that can be coupled at high speeds is important.

Features torquemeters HSTT series

- Measuring ranges from 50 Nm to 200 Nm

- Small group delay of the torque signal of 10µs

- Particularly suitable for highly dynamic measurements and controls

- Digital (frequency 60±20 kHz) and analogue (voltage ±10V, current 0 to 20 (24) mA) output

- eS version with very space-saving stator and separate evaluation electronics

- Interference-free transmission of measured values with contactless infrared telemetry

- CAN interface available as standard

- Calibration in our own DAkkS-certified calibration laboratory

RT1 series torque measuring flanges

The torque measuring flanges of the RT1 series round off the lower levels of the measuring range offered by ATESTEO. They are ideal for measuring drag torque. The torquemeters are based on tried and tested high-performance infrared LEDs (light-emitting diodes) for data transmission. These LEDs are completely immune to electromagnetic interference during optical signal transmission and do not radiate electromagnetic waves. The various connection options offer flexible adaptation.

Features torquemeters RT1 series

- Measuring range from 1 Nm to 20 Nm

- Standard measurement accuracy of 0.05% starting at a measurement range of 5 Nm

- Temperature measurement at several points for optimal temperature compensation

- High speed stability (speed strength) of up to 25,000 U/min (revolutions per minute) possible

- Optional: two torque measuring ranges

T series torque measuring flanges

The torque measuring flanges of the T series have two special features that are optionally available for other torque measuring flange models. One is that the measuring element is made of titanium. This results in a lower mass and mass inertia for highly dynamic measurement tasks. The second feature is that the T series torque measuring flanges have a central borehole on the rotor. This can be used to admit a second shaft or a wiring harness.

Features torquemeters T series

- Titanium rotor with a central borehole of 50mm

- Measurement range from 20 Nm to 500 Nm

- Standard measurement accuracy of 0.05 %

- Temperature measurement at several points for optimal temperature compensation

- High speed stability (speed strength) of up to 40,000 U/min (revolutions per minute) possible

- Optional: two torque measuring ranges

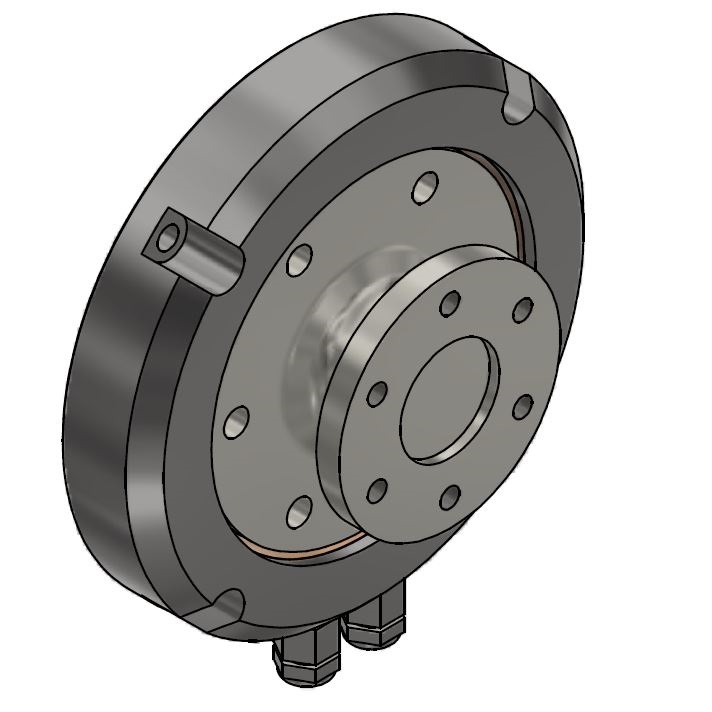

DST series torque measuring flanges

The torque measuring flanges of the DST-series are extremely compact torquemeters. They extend the ATESTEO product offering with robust and precise measuring systems for a wide range of applications in the manufacturing industry. The torque flange DST-series uses the well-established infrared telemetry for data transmission. The torquemeters are completely EMC-immune in optical data transmission and do not radiate any electromagnetic waves. The measuring body, mounted on a single side, allows higher accuracy when measuring on the output side. The various sizes of these torquemeters each cover an extremely large torque range.

Features torquemeters DST series

- Compact design

- Measurement range from 5 to 20 Nm (more ranges in preparation)

- Standard measuring accuracy 0.1%

- Frequency and voltage output

- Active temperature compensation

- Integrated rotational speed measurement as standard

- High-speed performance up to 20,000 rpm possible

- Single-side bearings for higher accuracy

- Flexible rubber couplings or metal below couplings available as options

Download

You can find all information about the innovative testing equipment with our torque transducers in our current performance brochure.