Vehicle equipment with precise measurement technology and adaptable telemetry systems

Drivetrain testing with vehicle equipment from ATESTEO

- Data validation

- Benchmarking

- Performance testing of components

- General vehicle testing

- Calibration of the ECU (electronic control unit) or TCU (transmission control unit)

- NVH (noise, vibration, harshness)

- Degree of effectiveness

- Component loading

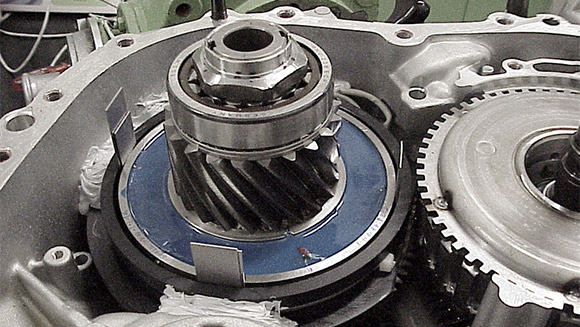

- Checking gear axis alignment (tumbling)

- RLD (road load data)

In our vehicle equipment area, ATESTEO offers you a full scope of measurement technology for equipping your passenger and commercial vehicles with technical measuring equipment. Our service range extends from vehicle instrumentation to conducting and analysing the measurements and test runs. With precise measuring equipment, specific data from series or prototype vehicles is collected and made ready for the development of new vehicle concepts.

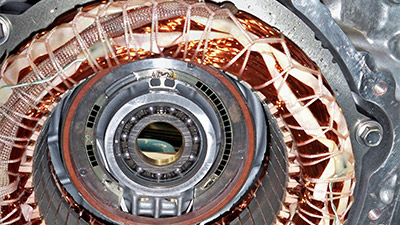

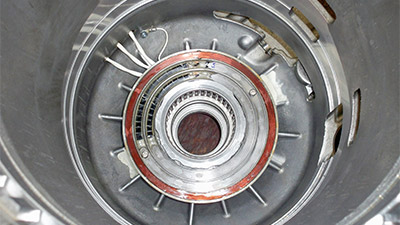

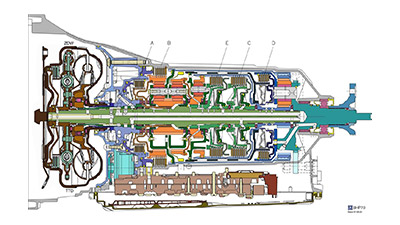

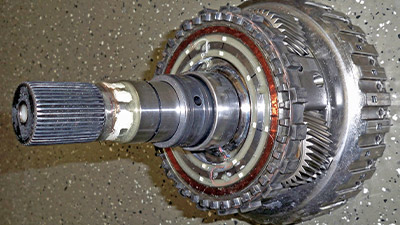

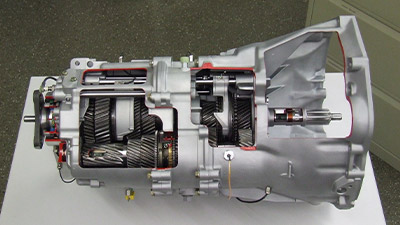

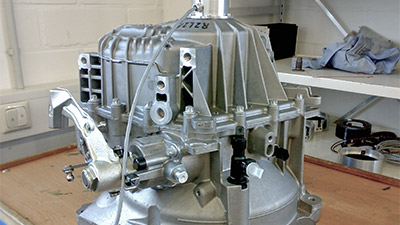

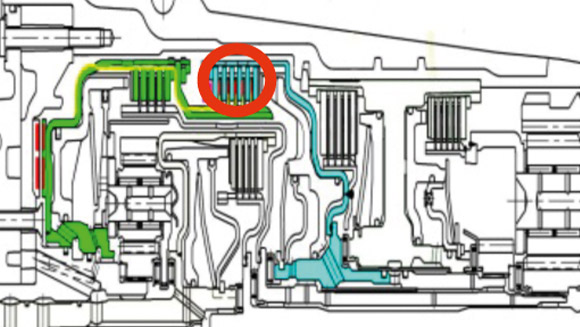

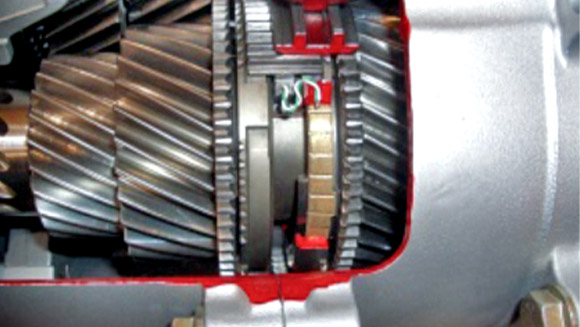

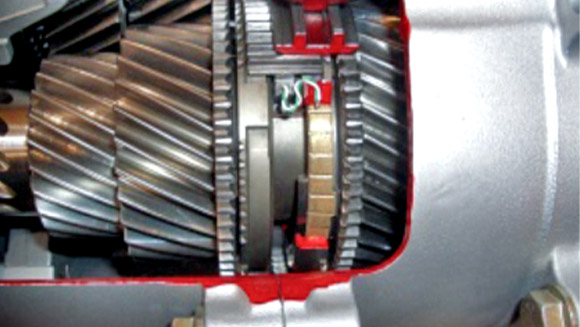

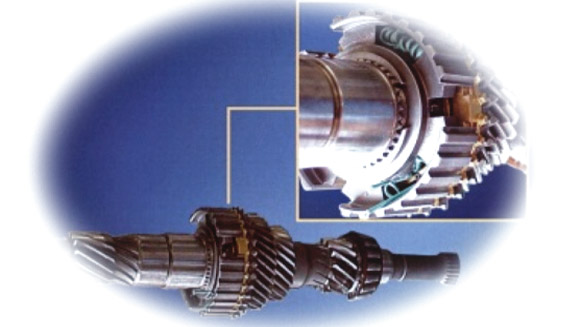

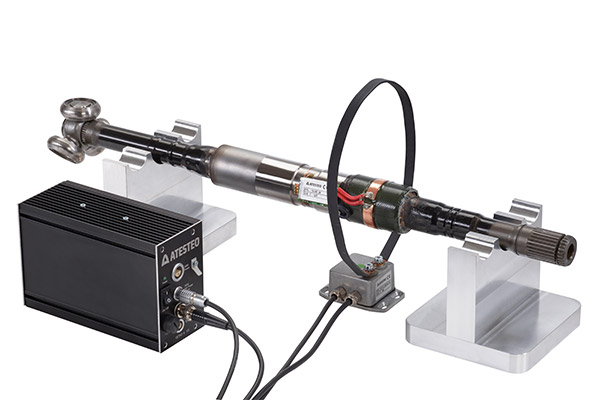

Depending on the scope of the measurement technology installed in the vehicle, on the basis of the captured data records, simple components can be more closely characterised and complex relationships exhaustively assessed. For this purpose ATESTEO equips the Drivetrain with highly adaptable telemetry systems that measure and transmit the various measured variables.

Highly-developed measuring equipment for the drivetrain

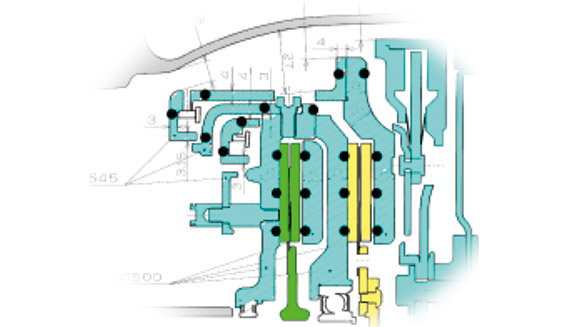

To determine the mechanical performance of rotating components, ATESTEO offers you highly specific telemetry systems that can be optimally adapted in their form and scope of function to the realities of innovative drive technologies. The optional central data collection enables synchronous processing of the measurement channels including the measured values read in through the vehicle bus (CAN). The functional reliability of more extensive installations is supported through fitting in an additional battery.

- Hybrid electrical vehicle

- Automatic transmission rear wheel drive

- Automatic transmission four wheel drive

- Manual transmission rear wheel drive

- Manual transmission four wheel drive

Contact

Do you have questions about our vehicle equipment? Please contact us. We are at your disposal.

We are looking forward to your message!

Measurements in the vehicle equipment

Torque measurements

- At side shafts and cardan shafts

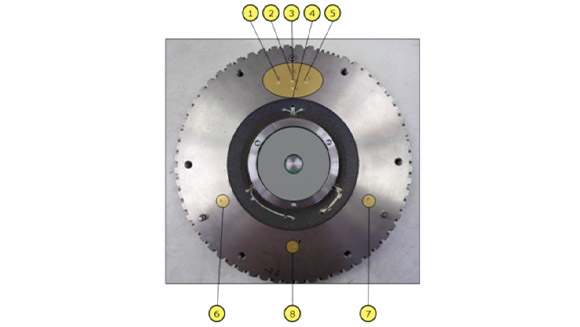

- On the engine flywheel

- On the flexplate

- On the transmission (gearbox) inlet (Manual transmission, Automated manual transmission, Automatic transmission, Double clutch transmission, Continuously variable transmission, hybrid)

- Within the transmission

- On the transmission outlet

Measurements on the entire vehicle

- Displacement

- Angle

- Acceleration

- Temperature

- Pressure

- Electrical quantities

- CAN

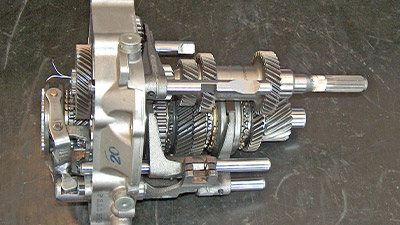

Temperature measurements

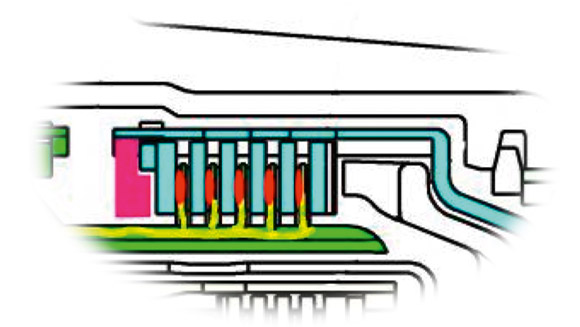

Collection of component temperatures during operation is needed when components do not meet expectations for their function and durability (service life). The information about temperature is also needed when, for example, additional temperature information for further compensation purposes is required with torque sensors which have already been applied. Because of their versatility, mainly thermocouples are used for one-channel or multi-channel measurement of temperatures on clutches, friction pairings, or gears. In close cooperation with the customer, the individual thermocouples are often placed very precisely with the help of electro-erosion (electro-discharge machining) methods.

- Clutch wet and dry

- Planetary transmission (Pinion)

- MT Synchronisation device

- Flywheel

Download

You can find further information on the ATESTEO solutions and services in the field of measurement technology in the ATESTESO Measurement Technology brochure.

Adaptable telemetry systems

ATESTEO offers five different telemetry systems to equip a drivetrain for measuring and transmitting various measured values such as torque, temperature, pressure, acceleration, and displacement. This variety assures a high probability of integrating the measurement technology into existing systems without functional negative impacts during a variety of operating conditions.

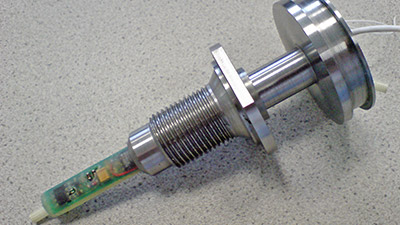

RFTS-1 telemetry

The telemetric RFTS-1 set is a complete set from ATESTEO for measuring torque and temperature in vehicle drivetrains. It contains all components for on-site installation:

- Stator element with antenna

- Rotor electronics

- Analysis unit VETAS

General data

- Easy to install and operate

- Deployable for strain gauges or thermocouples

- Non-contact (wireless) data and energy transmission with only one winding

- Up to 70 mm distance between the transmission coils

- Signal bandwidth 0…1 kHz (-3 dB)

- Power supply 9-36 V DC

- Low power consumption